Grinding Mill Filling Calculations

Grinding Mill Filling Calculations; ... Comminution energy efficiency calculated using ratio ... Effect of ball size and mill filling on grinding efficiency (U= and ...

WhatsApp)

WhatsApp)

Grinding Mill Filling Calculations; ... Comminution energy efficiency calculated using ratio ... Effect of ball size and mill filling on grinding efficiency (U= and ...

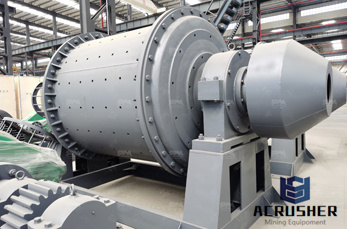

Ball Mill SlideShare. Nov 18, 2008 ... Introduction Ball mill is an efficient tool for grinding many materials into ..... of balls charge ratio to the volume of ...

Choose from our wide variety of grinding media for crushing and grinding in a mill. We carry ceramic grinding media, milling balls for wet and dry grinding

grinding media filling ratio . how to calculate raw mill grinding media ball mill ... how to calculate raw mill grinding media . how to calculate raw mill ...

CASE STUDY A mio t/a cement plant is having a closed circuit ball mill for cement grinding: The mill has been ... calculation of filling ratio of grinding mill;

The sizing of ball mills and ball milling circuits from laboratory grinding tests is largely a question of applying empirical equations or factors based on ...

The important issues on disposal of solid wastes from metal mines are to choose the right varieties for the comprehensive utilization of mining waste and to control ...

Nov 30, 2012· BINQ Mining > Mining Equipment > optimum charge filling for manganese ball mill; Print. ... calculation of ball filling ratio in grinding mill.

ball mill grinding ball selection and ratio . ... of grinding balls, the filling ratio or ... Hence a rod mill generally precedes a ball mill in a grinding ...

A study on the effect of ball diameter on breakage. kind of materials. Filling Ratio Of Grinding Mill Keywords: Ball mill, Ball size effects, Clinker, Grinding ...

Make: ABS Jumbo 54ND, Mild steel, Rpm: 2 850, Head height: 44 metres, 160 litres per min. Adele 081 490 3965/ desk Mike 082 410 4012/ m...

For real grinding of solids in a suspension using stirred ball mills, at equal grinding medium conditions (diameter, density, hardness and filling ratio), the ...

to the volumetric mill filling which influences grinding media wear rates, ... ratio ''H/Di'' and using ... the degree of grinding ball fill and pulp position for ...

The Ball Mill Filling Ratio Automatic Detection ... Figure 2 shows a typical set of bins for pan of the liner of a ball mill. TECHNICAL NOTES 8 GRINDING R. P ...

The influence of several grinding parameters such as charged material volume, ball filling ratio, and mill rotation speed on energy efficiency of fine grinding of ...

Ball Filling and Ratio of Feed to Grinding Balls ... percent volume of mill, and ratio of feed to grinding balls on the P80 of the grinding product were also developed.

calculation in filling ratio for ball mill. CHAPTER 14. Floor Area Ratio ... filling stations, ... calculation of hammer mill grinding capacity;

How to Brew Coffee. The NCA Guide to Brewing Essentials . Coffee is personal the right way to make it is how you like it best. That being said, mastering a few ...

Equipment Business:Filling ratio in a highpressure grinding mill. On April 30, 2017 April 30, ... the stone grinding mill equipment plays a very important role, ...

Optimization of continuous ball mills used for finishgrinding of cement by varying the L/D ratio, ball charge filling ratio, ball size and residence time

Attritor mill, intermittent type attritor, manufactured by Union Process, size 1S, type B, complete with stainless steel, jacketed tank. Tank measures 5" diameter x 6 ...

How to Select Suitable Ore Grinding Mill? rotation speed of grinding mill, filling ratio of the grinding media, More information about our machine, Chat Online+

iron ore ball mill grinding media filling ratio calculation. Galvanic Interaction between Chalcopyrite and Pyrite with Low Alloy . 17 Jul 2013 Wet milling in ball .

The Ball Mill Filling Ratio Automatic Detection System ..... and the grinding ball filling ratio is a major parameter of grinding of ore. ... The Ball Mill Filling ...

WhatsApp)

WhatsApp)