Improving Coal Pulverizer Performance and .

BallTube Mills This type of mill consists of a rotating tube ... Raw Coal Feeder Exhauster Hot Air Motor Coal Pulverizer Figure 1: Simplified diagram detailing a

WhatsApp)

WhatsApp)

BallTube Mills This type of mill consists of a rotating tube ... Raw Coal Feeder Exhauster Hot Air Motor Coal Pulverizer Figure 1: Simplified diagram detailing a

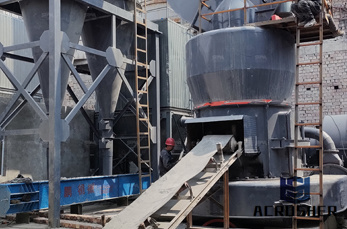

OPERATIONAL EXPERIENCE FROM THE UNITED STATES'' FIRST VERTICAL ROLLER MILL FOR CEMENT GRINDING By: Mark Simmons Production Manager Salt River .

· Practical 1: Title: Ball Milling Objective: To grind the coarse salt to a smaller size by using a ball mill and to obtain the particle size distribution of ...

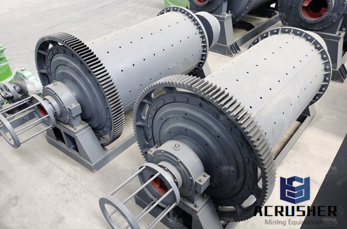

A ball mill is a type of grinder used to grind and blend materials for use in mineral dressing processes, paints, pyrotechnics, ceramics and selective laser sintering.

Design and Optimization of Ball Mill for Clinker Grinding in ... The performance of ball mill depends on ... an increase in throughput by 1520% and reduction in ...

This page is provide professional how to increase ball mill grinding rate information for you, we have livechat to answer you how to increase ball mill grinding rate .

Iron ore fines of −10 mm size and limestone are ground together in a ball mill to ... Influence of raw ... Influence of raw material particle size on quality ...

Ball Mill From China Zenith. This page is about the zenith Ball Mill for silicate, cement, ceramic,chemical fertilizer.

Whether ball mill or vertical roller mill (VRM), A TEC offers the expert solution for efficiency optimization to increase mill productivity and/or reduce mill power ...

Grinding trends in the cement industry ... 9 Ball mill from Sinoma for ... is a practical method in cases where the raw materials for clinker manufacturing are ...

Mls3726 Vrm Roller Mill ... installation cost of a vrm vs a ball mill. vrm roller raw mill maintenace ... Vertical Roller Mill repair Costs reduction Increase ...

in order to increase the flow of materials to be polished, and so to increase production capacity. ... The ball mill in the production of dry method, the fluidity is reduced ...

OPTIMIZATION OF PLANT OPERATIONS TROUBLE SHOOTING ... K#4 ball mill up gradation with installation of KHD RPS10 Roll Press for limestone ... increase in Raw .

Ball Mill/Grate Ball Mill/Overflow Type Ball Mill/Rubber Lined Ball... Shanghai MG is a young and dynamic factory exporting Grate Ball Mill,Overflow Type Ball Mill ...

PROCESS DIAGNOSTIC STUDIES FOR CEMENT MILL OPTIMISATION CASE STUDY Batra*, D. Bhaskara Rao** and Raju Goyal*** Holtec Consulting Private Ltd.,

Highlights Circulating load and classification efficiency effect on ball mill capacity revisited. Relative capacity model introduced and validated ...

Model Predictive Control for SAG Milling in Minerals Processing | 5 Model Predictive Control on a SAG Mill and Ball Mills The solution for the SAG Mill is an adaptive ...

Quick and Easy Black Powder Ball Mill Skylighter. How to optimize a 6 pound ball mill to safely and effectively ball mill homemade black powder.

· The smaller the specific size is, the easier the raw mixture is for ball mill . 3. Quality of cement mill Substantial scale cement ball mill can improve grinding .

A cement mill (or finish mill in North American usage) is the equipment used to grind the hard, nodular clinker from the cement kiln into the fine grey powder that is ...

Raw material preparation aims to preare a mixture that has the right chemical composition and particle size necessary for the clinker production.

Tube Ball Mill,Cement Mill,Raw Grinding Mill,Cement ... of quality grinding media for ball mill and keeps its position not increase grinding fineness of raw .

Thermal Energy Audit of Kiln System in a Cement Plant ... raw mill, coal mill ... are of ball mill type and other

adjusted classifiers for the raw meal and cement ... Getting more from the cement ball mill with ... installing a high efficiency classifier is to increase the mill

WhatsApp)

WhatsApp)